Table Of Contents

OEM (Original Equipment Manufacturer)

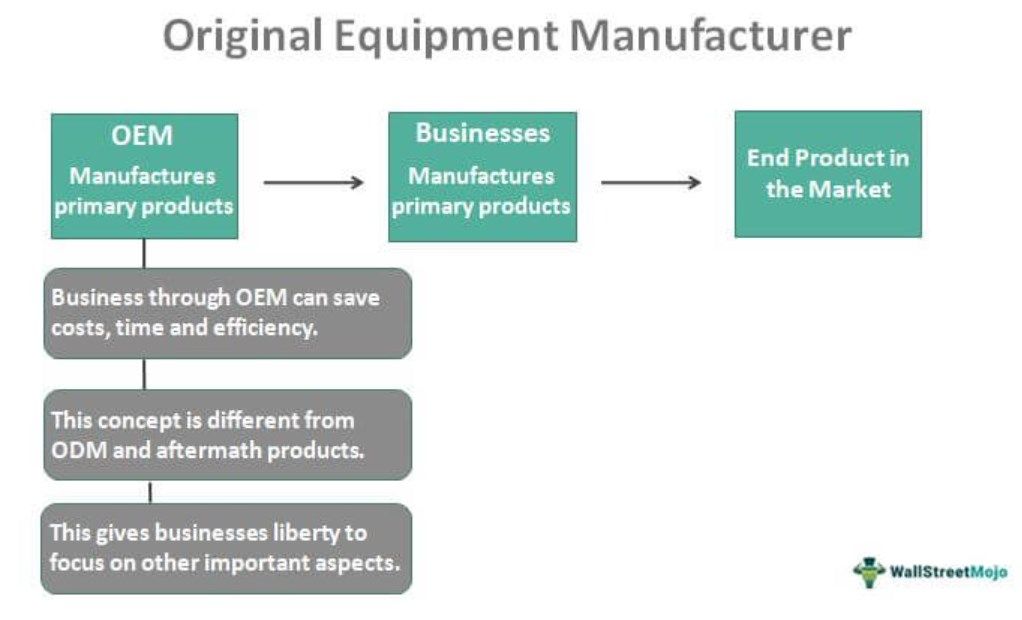

An original equipment manufacturer (OEM) is a company that provides technology and sells, distributes, or markets output devices that are used by other businesses for their end products. It is a business that fulfills orders from other companies by manufacturing its products in line with detailed requirements.

OEMs can save costs and time. Companies can focus on their primary business using third-party components rather than building every tertiary item or system from scratch. Businesses are not required to construct manufacturing facilities or manage OEM production internally. Instead, their systems use OEM components, which are marketed and sold under their brand.

Key Takeaways

- OEM is the acronym for the original equipment manufacturer, and they are companies that manufacture products for another company or partner company.

- Outsourcing the manufacture of the whole product or parts is beneficial to the company.

- It saves money and makes the process more efficient. In addition, it gives businesses the liberty to focus on other important aspects of their development.

- ODM, which stands for Original design manufacturing, differs from equipment manufacturing. ODM is concerned more about making modifications than manufacturing.

- Aftermarket products are different from original equipment manufacturer products. Aftermarket products, in comparison, are cheaper in quality.

OEM Explained

OEM is a company that manufactures products or components for other businesses according to their specifications. A dynamic business is created by outsourcing noncore tasks at the top or bottom of the supply chain, allowing for the most effective delivery of value and producing various components at a reduced cost to original equipment manufacturers. The businesses that purchase OEM parts are the Value-added resellers (VARs). They finish the products before reselling them under their brands. The original equipment manufacturer generally concentrates on selling to other businesses, or B2B sales, while the VAR focuses on marketing to the general public.

The OEM and VAR collaborate closely to design and develop goods tailored to the latter's demands.

A non-disclosure agreement (NDA), stipulating that all information provided by both parties will remain confidential, and both parties must sign it before communicating with potential OEMs. The criteria needs weighing from each original equipment manufacturer after the comparison of OEMs. Choosing an OEM involves two steps. The first step is selecting a location, which considers topography, social and cultural conditions, industrial facilities, transportation accessibility, and resource availability. One must follow the rules and regulations when choosing the site and the credibility of the local government that holds sway over the region. After selecting a site, the next step is to choose an OEM firm. The purchasing department can choose a manufacturing company using a supplier selection methodology while considering pricing, quality, delivery, and other factors.

Examples

Check out these examples to get a better idea of OEM:

Example 1 - OEM Automotive

ABC ltd is a car manufacturing company. They want to mass-produce automobiles. However, their plant cannot accommodate the new production numbers. Adding a new plant would mean a high financial burden. The one way out is to outsource the manufacturing of certain parts of the car and then assemble them on their premises. The company to which ABC has outsourced certain parts is the original equipment manufacturer or real OEM.

Example 2

Nike is a multinational firm based in the United States that creates, develops, produces, markets and sells footwear, clothing, equipment, accessories, and services globally. The company had contracted with the renowned Hong Kong-based manufacturer, Esquel Group, to handle its manufacturing. Esquel Group offers manufacturing services and holds the capacity to buy the supplies from the supplier. In actuality, this setup is referred to as "turnkey". Esquel Group here is the original manufacturer, i.e., real OEM. Nike and Esquel Group here use consignment contracts. Similarly, another famous brand, Calvin Klein outsources its manufacturing and material procurement to Li & Fung, a turnkey company.

Significance of OEM

Companies partnering with OEMs, manufacturers, or resellers can efficiently use their cost budget. In such a case, these organizations need not build spaces for manufacturing or handling in-house production. The products produced by OEM tend to be cheaper due to this. OEM products, components, and parts increase the lifespan of the product of the partner firm, ensuring top performance while saving money on replacement parts and boosting the business. The consumer who buys the system or product typically benefits from the company's cost savings.

OEM vs. ODM

ODM, or Original design manufacturing, involves corporations choosing existing products, modifying them, and then selling them under their brand name. At the same time, original equipment manufacturer produce products to a company's specifications. The OEM gives the design of a product to an OEM. The OEM will then sell the goods under their brand after receiving them from the ODM. The use of ODM is advantageous to manufacturers. When the need for new technology arises, they may implement and speed up the process, making it simple to upgrade the goods quickly. In addition, ODMs have the ability to produce goods in large quantities.

OEM vs. Aftermarket

The original equipment manufacturers' parts are produced by the same business that builds the product. However, a different parts manufacturer often handles the production of aftermarket components, which suits as many models as possible. As a result, aftermarket parts cannot achieve the superior fit of original equipment manufacturer components because of these design variations.

Although aftermarket parts may initially be less expensive, the drawbacks outweigh any early savings. Aftermarket parts may not necessarily be constructed from the same superior materials as OEM parts, which is one factor that contributes to their lower cost. Aftermarket parts made of these below-par materials may malfunction, negating any initial savings an organization may have enjoyed.