Table of Contents

Fourth-Party Logistics (4PL) Meaning

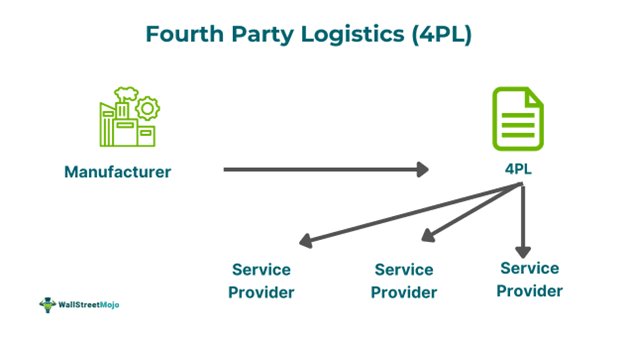

Fourth-party logistics (4PL) is an operational model where the manufacturer outsources their entire supply chain management to an external provider. With this, the external provider becomes responsible for managing, assessing, designing, building, running, and maintaining solutions on behalf of the manufacturer.

4PL serves as a single point of contact between the manufacturer and several other logistic solutions providers. These partners manage and communicate with all other service providers, alleviating the burden of coordination. With the growth of the logistics industry, 4PL has emerged as a key factor in the whole supply chain management.

Key Takeaways

- Fourth-party logistics refers to outsourcing the complete supply chain management to one single logistics provider, who acts as a single point of contact between the manufacturer and multiple service providers.

- 4PL offers a holistic approach, cost reduction, well-integrated tasks, better efficiency, and customer satisfaction.

- On the contrary, 4PL companies take away control, become expensive with customized and premium solutions, and manufacturers become highly dependent on them.

- Third-party logistics mainly takes care of picking, packing, and shipping. On the other hand, 4PL firms offer business planning inventory management along with whole 3PL services.

Fourth-Party Logistics Explained

Fourth-party logistics is an outsourcing model where a company outsources its complete supply chain management, including the logistics operations, to an external provider with 4PL support. The 4PL firm manages, designs, builds, assesses, monitors, and maintains the complete supply chain process along with other operations with major authority and control on behalf of the manufacturing company. These companies hold special experience and expertise in assisting businesses in their logistic operations and streamlining their processes. Moreover, they offer more efficient and cost-effective solutions compared to their self-made structures.

With fourth-party logistics companies, businesses enjoy a series of benefits and a wide range of logistics services that are tailor-made, exclusive, and fulfill the demands and needs of their supply chain management. They increase work flexibility and use tools and advanced technologies to improve the overall efficiency of the logistics operations. Furthermore, these firms operate with a resilient support team and provide customer satisfaction by always seeking improvements. Working with a 4PL firm ensures peace of mind for retailers when it comes to fulfilling their unique supply chain needs and minimizing their effort, time, and capital.

Fourth-party logistics providers respond quickly to any unexpected event or logistics issue. They have the data to study, understand, and predict businesses' future demands. In addition, they involve planning, assessing, and total administration to reduce labor costs and use the present resources optimally.

Examples

Below are two examples to help you understand the concept better:

Example #1

Suppose a furniture manufacturer ABC requires inventory, raw materials, and other parts and subparts, including logistics and supply chain management. Since the manufacturer lacks a workforce, it hires a 4PL firm, LogiPlus Solutions, to take charge of the complete supply chain management.

LogiPlus Solutions becomes ABC's single point of contact and manages the entire supply chain process. It optimizes operations, communicates, and removes the burden on ABC to contact multiple providers separately. This increases productivity and performance and is a cost-effective way for ABC.

Example #2

In a press release, XPO announced a new three-year partnership with global crop protection leader UPL. This partnership will focus on delivering fourth-party logistics solutions.

UPL is known for offering solutions to the agriculture ecosystem. It has a sales presence in over 130 nations, including major hubs and production sites across Belgium and France. On the other hand, XPO has customized its 4PL solutions to meet UPL's particular needs. This includes freight audit and pre-billing services, as well as focusing more on sustainability through a collection of CO2 emission measurements.

Advantages And Disadvantages

The advantages of 4PL are listed below:

- 4PL offers holistic oversight and monitoring of the entire supply chain. Moreover, it optimizes the logistics process.

- It takes off the burden of contacting, communicating, and managing multiple service providers.

- It is cost-efficient for the manufacturer and is an affordable means of outsourcing.

- The 4PL companies tend to leverage historical data and forecast their client's needs and specific demands.

- All the logistic operations become integrated, working together as a well-established framework.

The disadvantages of such a logistics solution are listed below:

- One of the most crucial disadvantages of 4PL is the lack of control. They tend to operate independently and with complete authority over the supply chain.

- When businesses demand customized services and premium solutions, they become expensive and come at higher costs.

- When a manufacturer outsources operations to a 4PL, they become dependent on them and are exposed to the risks of meeting the manufacturing deadlines.

Finding the right 4PL company that matches and fulfills the outsourcing criteria requires risk and time.

Third-Party Logistics Vs. Fourth-Party Logistics

The main differences between third-party (3PL) and 4PL are:

- 3PL focuses primarily on logistics solutions, but 4PL manages the entire supply chain management.

- 3PL is the only service provider in the operational model. Still, when it comes to 4PL, they act as a single point of contact and are responsible for overseeing communication and managing multiple logistics solution firms.

- 3PLs have limited applicability and scope, but with the emergence of the logistics industry, 4PLs have become more advanced, effective, and opted for by manufacturers.