Table Of Contents

What Is Fast-Moving Inventory?

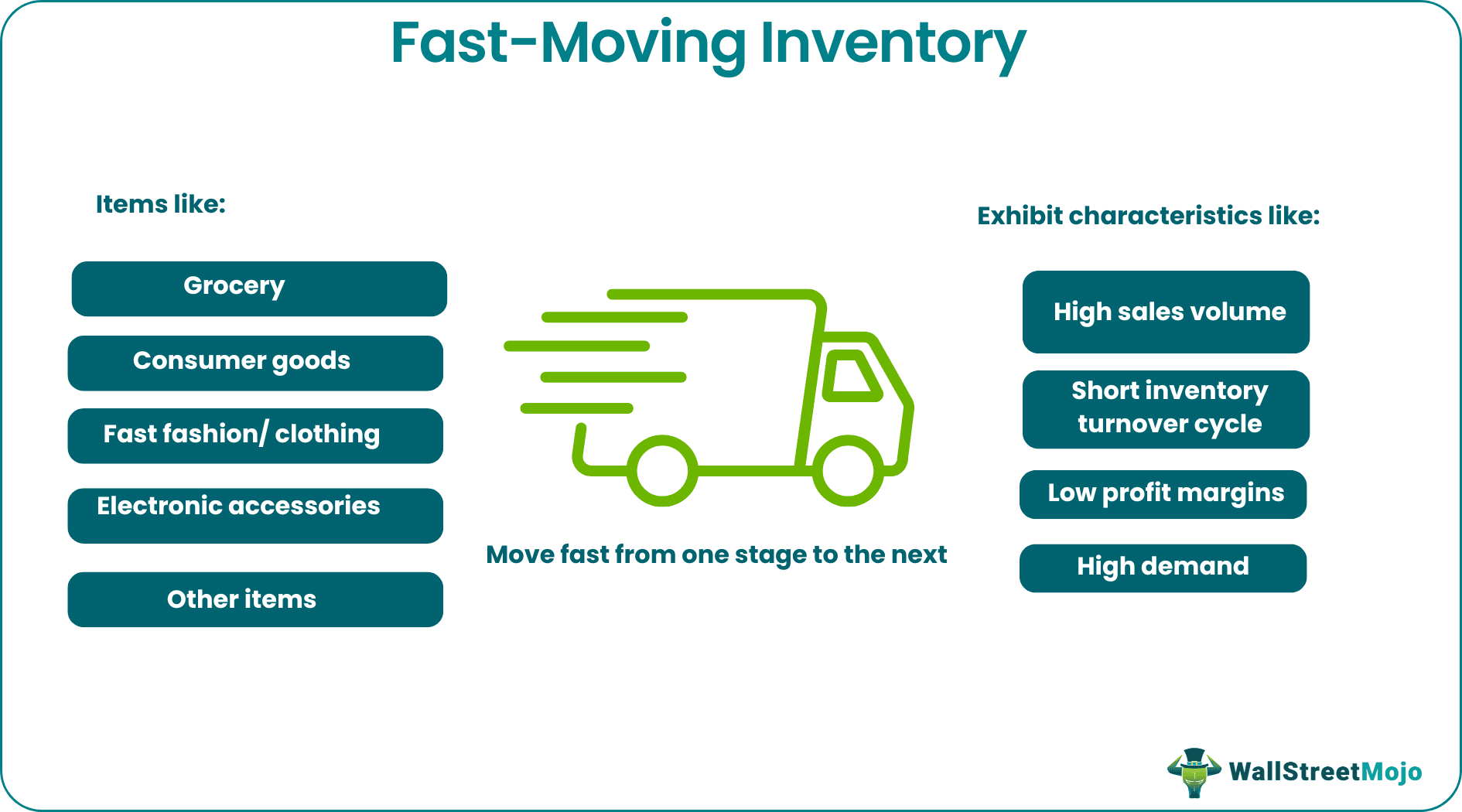

Fast-moving Inventory refers to products that sell quickly. Such products call for frequent stock replenishments due to a high inventory turnover rate. They comprise around 10-15% of the total inventory in an enterprise. These products are in high demand, leading to high sales. To meet this demand, they are refilled frequently. It also enhances customer satisfaction.

Fast-moving items include perishable items, consumer goods, groceries, etc. These items have low profit margins. This inventory management system helps businesses optimize stock levels, decrease stockouts, and enhance stock management holistically. It is of great use in retail, manufacturing, and e-commerce sectors, where meeting customer demands, avoiding delays, and maintaining customer satisfaction levels are crucial performance metrics.

Key Takeaways

- Fast-moving inventory consists of goods that do not need to be stored in the warehouse or store for a long time. They need frequent restocking since they constitute around 10-15% of the total inventory.

- These goods help businesses meet high customer demand, maximize sales, and ensure high customer satisfaction.

- It has items that briskly traverse the supply chain, whereas non-moving items remain stagnant and unpurchased, occupying valuable storage space and tying up capital.

- Certain key parameters are measured as part of its computation process. These include the average time of stay, consumption rate, percentage of stay, inventory turnover ratio, holding cost, etc.

- Essential items are typically classified as fast-moving goods. Increased customer satisfaction, supply chain efficiency, timely deliveries, operational benefits, and financial optimization are some characteristics of such inventory.

Fast-Moving Inventory Explained

The fast-moving inventory definition states that such inventory consists of high-velocity or fast-turning inventory of goods and commodities that operate on the rule of quick sales and high demand. These items are typically sold and replaced within a year. The stocks mandate vigilant tracking to prevent overstocking or stockouts. However, if these inventories are properly managed, they provide a competitive edge to businesses in a fast-paced marketplace. They contribute heavily to the revenue and sales of a company despite constituting a relatively minuscule percentage of a business's inventory.

The efficient working of fast-moving items depends on how efficiently a business clears its inventory, which is referred to as the inventory turnover. A high inventory turnover rate depicts effective inventory management, indicating that goods are sold and revenue is generated without the stock remaining idle at any given point in time. Such inventory does not require large storage space, which is crucial to optimizing stock levels, reducing stockouts, and following better inventory management practices.

Fast-moving inventory analysis helps optimize stock levels for efficient operations. The Fast, Slow, and Non-moving (FSN) analysis helps segregate products by quantity, consumption, and inventory rate. As a result, resources and techniques of inventory management can be defined and executed well. Businesses employ fast-moving inventory analysis techniques for improved decisions like stock optimization, placing purchase orders, merchandising, and finalizing items for restocking.

Consequently, it boosts the efficiency of the supply chain, resulting in timely replenishment and reduced production disruptions. Also, fast-moving inventory analysis helps optimize stock levels for efficient operations. It has a significant impact on the return on investment (ROI) and cash flows of a business.

Enterprises enjoy positive cash flows and higher ROI by minimizing slow-moving inventory. Additionally, FSN analysis and ABC analysis helps businesses with correct item classification, leading to better inventory control and cost management. Hence, the inventory carrying costs are reduced while profitability increases.

How To Calculate?

For effective inventory management, slow-moving and fast-moving inventory analysis is crucial. It helps identify and calculate stock levels. FSN analysis enables personnel to calculate and identify the fast-moving inventory of retailers.

One can conduct FSN analysis stepwise as below:

Step 1

Find Average time of stay = Cumulative no. of inventory holding days ÷ (total quantity of items received + opening balance)

Step 2

Compute consumption rate = Total issued quantity ÷ Total period duration

Step 3

Determine the cumulative average time of stay = Average stay of the item + average stays of all items that stay longer in inventory than itself

Step 4

Calculate cumulative consumption rate = Consumption rate of item + consumption rate of all items consumed faster than itself

Step 5

Find percentage average time of stay = (Cumulative average stay of item ÷ cumulative average stay of all items) x 100

Step 6

Find percentage consumption rate = (Cumulative consumption rate of item ÷ cumulative consumption rate of all items) x 100

Step 7

Inventory Turnover Ratio = Cost of Goods Sold / Average Inventory Value

Step 8

Inventory Holding Cost = (Storage costs + Employee salaries + Opportunity costs + Depreciation costs) / Total value of annual inventory

After calculating the above values, one must apply the following parameters to ascertain whether an inventory is fast-moving.

| Parameter | Condition | Is it fast-moving? |

|---|---|---|

| Average Consumption Rate | Has a high consumption rate | Yes |

| Inventory Turnover Ratio (ITR) | Has a value of more than 3 | Yes |

| Average Stay | Quick movement time | Yes |

| Number of average days to sell | Least number of days to sell | Yes |

| Holding Costs | Low holding costs | Yes |

| Average cumulative stay | Staying only for less than or equal to 10% of the average cumulative stay | Yes |

| Cumulative consumption rate | 70% of the average consumption rate | Yes |

Examples

Let us use a few examples to understand the topic.

Examples #1

Suppose a business XYZ Corporation has an inventory of a specific product B, for which it tracks the following data over a year:

- Total items received: 500

- Opening balance: 100

- Total issued quantity: 450

- Total period duration: 365 days

- Cost of Goods Sold (COGS): $50,000

- Average Inventory Value: $20,000

- Storage costs: $2,000

- Employee salaries: $5,000

- Opportunity costs: $3,000

- Depreciation costs: $4,000

Let us calculate step by step:

Step 1: Find the average time of stay

Average time of stay = (Cumulative no. of inventory holding days) / (Total quantity of items received + opening balance)

Average time of stay = (365 days) / (500 + 100) = 0.609 days per item

Step 2: Compute consumption rate

Consumption rate = Total issued quantity / Total period duration

Consumption rate = 450 / 365 = 1.23 items per day

Step 3: Determine cumulative average time of stay

For this example, let us assume that the cumulative average time of stay for products that stay longer in inventory than themselves is 1.5 days per item. This step entails computing the cumulative average time of stay for those goods.

Step 4: Calculate the cumulative consumption rate

Assume that each day, the total number of items consumed surpassing its own pace is 1.8.

Step 5: Find the percentage average time of stay

Percentage avg time of stay = (Cumulative average stay of item / cumulative average stay of all items) x 100

Percentage avg time of stay = (0.609 / 1.5) x 100 = 40.6%

Step 6: Find the percentage consumption rate

Percentage consumption rate = (Cumulative consumption rate of item / cumulative consumption rate of all items) x 100

Percentage consumption rate = (1.23 / 1.8) x 100 = 68.3%

Step 7: Inventory Turnover Ratio (ITR)

ITR = COGS / Average Inventory Value

ITR = $50,000 / $20,000 = 2.5 (not greater than 3 as required for fast-moving inventory)

Step 8: Inventory Holding Cost

Inventory Holding Cost = (Storage costs + Employee salaries + Opportunity costs + Depreciation costs) / Total value of annual inventory

Inventory Holding Cost = ($2,000 + $5,000 + $3,000 + $4,000) / $20,000 = $14,000 / $20,000 = 0.7 or 70%

According to the parameters given to determine the type of inventory:

- Average Consumption Rate: Not high enough

- Inventory Turnover Ratio (ITR): Not greater than 3

- Average Stay: Longer than expected

- Number of average days to sell: Not the least

- Holding Costs: Not low enough

- Average cumulative stay: Not staying for less than or equal to 10% of the average cumulative stay

- Cumulative consumption rate: Not reaching 70% of the average consumption rate

Looking at these parameters, one finds that this specific inventory item, B, does not meet the criteria for fast-moving inventory. So, inventory B of XYZ Corporation is not a fast-moving item.

Examples #2

Suppose Laura, a tech-savvy businesswoman, owns an electronics store named TechnoMart in the busy metropolis of Veridian (a fictional city). She was adept at spotting fast-moving inventory and anticipating trends. The futuristic VR glasses called VirtuVision, produced by the well-known company OmniTech, were one of her most popular items. Gamers and computer enthusiasts went to TechnoMart to explore the immersive virtual reality environment, and these stylish glasses flew off the shelf.

Laura demonstrated her grasp of rapidly moving goods by forming a strategic alliance with OmniTech, which guaranteed a consistent supply of VirtuVision spectacles. TechnoMart's success cemented Laura’s status as the Tech Guru of the city by making it the go-to place in Veridian for the newest tech products. Hence, by identifying fast-moving goods and managing them well, Laura could grow her business.

Importance

Fast-moving inventory or goods constitute the most used items with the highest turnover rate in the entire inventory of a business. Such items are important to consumers as these goods generally meet a consumer’s daily necessities. The importance of essential items in a consumer’s life cannot be ignored. Items like eggs, fruits, vegetables, milk, over-the-counter drugs, etc., are needed in the everyday lives of consumers.

- Customer satisfaction and sales: These are the items that customers are most likely to purchase frequently and repeatedly. By ensuring that these items are made available to customers consistently, businesses can promote customer loyalty and drive sales. Happy customers are more likely to buy again from a business that consistently meets their needs. This leads to increased revenue generation and fosters long-term customer relationships.

- Supply Chain Efficiency: Consistent maintenance of fast-moving inventory results in a healthy supply chain. These items usually have a higher demand and shorter lead times than other items. Hence, managing them and predicting the supply chain movement becomes easy. It ensures faster inventory turnover, low stockouts, and improved overall supply chain performance.

- Timely Deliveries: It also ensures that essential items are delivered to customers on time. By making these items readily available, businesses can fulfill orders, meet customer expectations, and establish and maintain a positive brand image.

- Operational Benefits: As such inventory has a high turnover rate, it contributes to reduced holding costs, improved cash flows, and optimized space utilization inside the warehouse.

- Financial Optimization: It leads to lower carrying costs, enhanced profitability, decreased risk of stockouts or overstocking, and waste and obsolescence mitigation.

Fast-Moving Inventory vs Non-Moving Inventory

The differences between fast-moving and non-moving inventory have been listed in the table below.

| Basis | Fast-Moving Inventory | Non-Moving Inventory |

|---|---|---|

| Definition | Items of this category have a high consumption rate, require frequent replenishment, and move fast. | Items remain unused or unsold for a long time. |

| Inventory turnover rate | It has an inventory turnover ratio of more than 3. | It has an inventory turnover ratio of less than 1. |

| Portion of the total inventory | Such inventory accounts for almost 10 to 15% of the total inventory. | It accounts for 60 to 65% of the total inventory. |

| Profit margin | These items have a lower profit margin than other inventory types. | It is not applicable as these commodities are not sold. |

| Average stay | It has a low average stay in the inventory since items move fast through the supply chain. | It is not applicable as these commodities are not sold. |

| Management approach | It needs more attention than slow-moving inventory. | It does not require much attention or care. |

| Replenishment cycle | Items have to be replenished more often than others. | Items are mostly damaged or obsolete or were not shipped within a specified time. |

| Warehousing requirements | It does not occupy space in the warehouse since it moves fast from one stage to the next. | It usually occupies the warehouse for a long time. |

Frequently Asked Questions (FAQs)

Careful management is necessary to ensure the availability of items and reduce stockouts in fast-moving inventories. It consists of high-turnover commodities such as basic everyday products, over-the-counter medications, and food, among several other things. Businesses should maintain higher stock levels, prioritize resources, and improve monitoring and control techniques to manage fast-moving inventory properly.

Items that sell quickly and do not need to be kept in stock for a long time are known as fast-moving items. Dairy, eggs, fruits, vegetables, and over-the-counter medications are a few examples. These products usually have a small profit margin and must be manufactured often. About 10% to 15% of the overall inventory is often made up of fast-moving goods, which typically have an inventory turnover ratio greater than 3.

Inventory that moves slowly is made up of products that sell at a slower rate than inventory that moves quickly. Slow-moving items comprise around 30%–35% of inventory. In contrast, at 10%–15% of inventory, fast-moving items with a high turnover ratio are regularly used.