Table Of Contents

What Is EOQ(Economic Order Quantity)?

EOQ stands for economic order quantity. It helps to find a production volume or order that the company should add to minimize the holding cost and order cost. It is the ideal or the best quantity that the manufacturer will purchase that will be able to meet the consumer or business demand as well as remain within the optimum cost levels.

This concept arises from the fact that the cost remains under control but the required demand is met. But it can be applied best in cases where the demand and cost does not fluctuate overtime. The quantity can be determined using any particular software or through the use of mathematical formula and help in reduction cash blockage due to unnecessary production or purchase.

EOQ Explained

The EOQ refers to the economic order quantity that explains the optimum level of order that that business should place, and which will be able to meet the required demand of the business and clients along with meeting cost levels.

In the process, the inventory cost levels remain within limits and balances with the cost of the order. Proper analysis will show that in an ideal situation when the ordered volume increases, the holding or the inventory cost will also rise along with it. But the overall ordering cost comes down.

The concept of economic order quantity equation helps in cash flow management by bringing a balance in the quantity of orders and funds required for the same. It is necessary to strike this balance because inventory is extremely essential because it is the main asset that helps to run the business. But it is important to keep it in proper quantity which is neither too high nor too low. Too low quantity will result in loss of sales and too high will lead to blocking of funds that can be used for other more useful investments and areas of business.

The process of calculating EOQ can be either computerised of manual. But it helps in determining the actual order level. The formula is such that it will automatically trigger the requirement to place further order immediately to avoid shock shortage, else it will lead to loss of revenue and customer base.

Formula

Let us look at the critical components of EOQ and its formula –

#1 - Holding Cost

Holding cost is the cost of a holding inventory in storage. The direct cost needs to be calculated to find the best opportunity to store inventory or, instead of investing it somewhere else- assuming demand to be constant.

H = i*C

Where,

- H= Holding cost

- i= Carrying cost

- C= Unit cost

As demand is constant, inventory will decrease with usage when it reduces to zero-order placed again.

#2 - Ordering Cost

Ordering is the cost of placing an order to the supplier for inventory. The annual quantity calculates the number of orders demanded divided by the volume per order.

Number of orders = D / Q

Where,

- D = Annual quantity demanded

- Q = Volume per order

- Annual Ordering Cost

An annual ordering cost is the number of orders multiplied by ordering costs.

Annual ordering cost = (D * S) / Q

Where,

- S = Ordering cost

#3 - Annual Holding Cost

Annual holding cost is the sum of volume per order and holding cost, which can be written as.

Annual Holding Cost= (Q * H) / 2

#4 - Total Cost

The sum of the two costs gives an annual total cost of an order.

We get the below equation by adding annual ordering and holding costs.-

Annual Total Cost or Total Cost = Annual ordering cost + Annual holding cost

Annual Total Cost or Total Cost = (D * S) / Q + (Q * H) / 2

To find EOQ – Economic Order Quantity Formula, differentiate total cost by Q.

EOQ = DTC / DQ

EOQ = √ (2SD/H)

Examples

Let us understand the concept of economic order quantity equation with the help of a suitable example.

Example #1

Let’s take an example to calculate EOQ – Economic Order Quantity for a pen manufacturing company where the company’s annual quantity demanded is 400, the holding cost is $2, and the ordering cost is $1. Now we will put these values in the above equation.

In the below-given figure, we have shown the calculation for the EOQ for a pen manufacturing company.

So, the calculation for EOQ 2 = (2*400*1)/2

Therefore ,EOQ =20.

Example #2

Let us understand this with an example. A company named Den Pvt. Ltd. wants to know EOQ as it is a tool to calculate the volume and frequency of orders required to minimize the cost per order.

The below-given table is the data for the calculation of EOQ – Economic Order Quantity Formula for company Den Ltd.

Take the below assumption.

By keeping the above values in the below tabular equation, we get the total cost with different volumes.

Through the above data, we get below the graph.

From it, we can see that EOQ is 250. Hence, EOD sets a point that minimizes the cost of inventory.

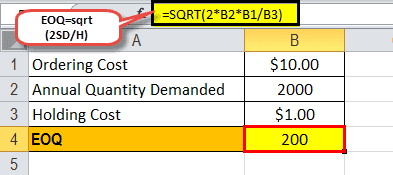

Example #3

A company manufactures steel boxes that it needs to calculate the quantity required. EOD needs to be calculated.

Taking below Assumptions:-

- Ordering Cost = $10 per order

- Annual quantity demanded = 2000 units

- Holding cost = $1 per unit

In the below-given figure, we have shown the calculation of the EOQ for a manufacturing company.

So, the calculation for EOQ2=(2*2000*10)/1

EOQ = (40000)1/2

Therefore, EOQ = 200

Further, we will calculate holding, ordering, and the number of orders per year and combine ordering and holding costs at economic order quantity.

- Numbers of orders per year

The below table shows the calculation of the number of orders per year.

A number of orders per year = Annual quantity demanded/ EOQ.

So, the calculation of EOQ for the number of orders per year is =2000/200

Therefore, several orders per year =10

- Ordering Cost

The below table shows the calculation of the Ordering cost.

Ordering cost = Number of orders per year * cost per order

So, the calculation of EOQ for ordering cost is = 10*10

Therefore, ordering cost = 100

- Holding Cost

The below table shows the calculation of the Holding cost.

Holding cost = Average unit * Holding cost per unit

So, the calculation of EOQ – Economic Order Quantity Formula for holding cost is = (200/2) * 1

Therefore, holding cost = 100

- Combine ordering and holding costs at economic order quantity

The table below shows the combined ordering and holding cost calculation at economic order quantity.

Ordering cost + Holding Cost

So, the calculation for combining ordering and holding cost at economic order quantity formula is = 100 + 100

Here, holding and ordering costs are the same, i.e., $100.

Therefore, combining ordering and holding costs at the economic order quantity formula is= 200

Let’s see how we can derive the same.

From this table, we also get EOQ = 200.

From the above examples we can clearly understand the concept along with how to use the formula to derive the ideal quantity that will is suitable to meet customers and business needs as well as reduce cost of ordering and operations.

Relevance And Uses

Let us find out some of the important uses of the concept in the industry.

- Cash flow planning- EOQ formula is used to minimize the cost of inventory and save cash.

- Reordering Point- This formula calculates the reordering point, i.e., the point at which one gets a trigger to order inventory.

- It helps the company to reduce waste. The optimum order levels determined is such that it will be neither too high nor too low. Too high levels will lead to wastage of goods or inventory, especially if their storage life is less, or is perishable in nature.

- It helps to minimize storage and holding costs.

- Ordering the right level will ensure that there is no unnecessary blockage of storage space as well as funds, which can be used for better and more productive purpose.

- This is a very effective ordering strategy that that helps in planning and determining the time and the point at which order should be placed so that there is no loss of revenue and fall in profits. The order is placed at the most efficient interval of time.

- The planning for production and supply can be made through proper schedule after tracking the raw material procurement time and quantity. The flow of raw material remains uninterrupted without any shortage or excess.

- From the above points is can also be derived that such a planned process ensures that relation with the suppliers also remain good. Since orders are placed at certain preplanned timings, it becomes easy for suppliers to plan their sales and dispatch well in advance, avoiding any last-minute rush and mismanagement.

- Using this concept, a business can mitigate risk of supply and order mismanagement or waste. Over ordering lead to the risk of obsolescence and less order will lead to risk of loss. EOQ will help in maintaining a steady performance of the supply chain or risk of loss.

- The capital is also used in an optimum manner because it minimizes the capital that is tied up in the order. Thus, resources are allocated in an efficient manner to generate maximum returns.

Thus, the above are some noteworthy advantages and uses of the concept. It is necessary for manufacturers to follow this method to avoid any cost or order related mismanagement.