Table of Contents

What Is Closed Loop Supply Chain (CLSC)?

A closed-loop supply chain is a system where products and materials are recycled or reused at the end of their life cycle, creating a continuous loop of resources. This approach aims to minimize waste and environmental impact by efficiently managing the flow of goods from production to disposal, thereby promoting sustainability and circular economy principles.

In a closed-loop supply chain design, benefits are reduced waste, lower environmental impact, and cost savings through material reuse. However, challenges such as increased complexity in logistics, higher initial investment for infrastructure, and potential quality control issues in recycled materials may arise. While closed-loop systems promote sustainability, they require careful planning and management to overcome logistical and operational challenges.

Key Takeaways

- Closed-loop supply chains aim to minimize waste and environmental impact by reusing resources, contributing to sustainability and resource conservation.

- It focuses on reusing, refurbishing, or recycling products and materials within the supply chain. This process prioritizes sustainability by reducing waste generation and environmental impact.

- It captures additional value from returned or used products. However, unusable or worn-out products are discarded. This process promotes circular economy principles by prolonging the lifespan of resources.

- However, efficient reverse logistics processes are required to handle returned products or materials.

How Does A Closed Loop Supply Chain Work?

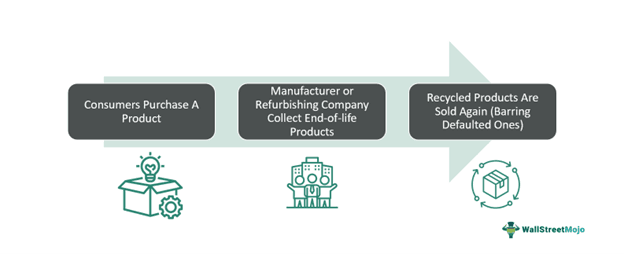

In a closed-loop supply chain, products and materials are recycled and reused within the same system, creating a circular flow of resources. The process begins with the collection of used or end-of-life products from consumers or other points in the supply chain.

These products are then sorted, disassembled, and refurbished or remanufactured to meet quality standards. Once refurbished, the products are reintroduced into the supply chain, either for resale or as components for new products.

Critical components of a closed-loop supply chain include reverse logistics, which involves the collection and transportation of used products, and remanufacturing facilities where products are refurbished or rebuilt. Advanced tracking and tracing technologies help monitor the movement of materials throughout the closed loop, ensuring efficient resource utilization and minimizing waste.

One classic case of closed-loop supply chain management can be found in the automotive industry. Here, manufacturers collect end-of-life vehicles and recycle components such as engines, transmissions, and body panels. These components are refurbished and reused in the production of new vehicles or sold as replacement parts.

By implementing closed-loop systems, companies can reduce reliance on virgin materials, minimize environmental impact, and lower overall production costs. However, effective implementation requires collaboration among stakeholders, investment in infrastructure, and robust quality control measures to ensure the integrity of recycled materials.

Diagram

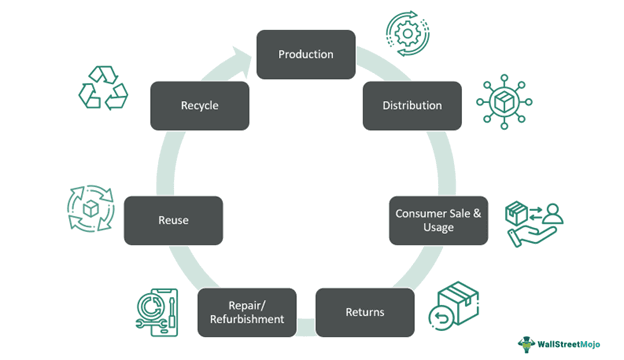

A looped process such as the closed loop supply chain management process can be better understood through a pictorial representation of the cycle. The diagram and a brief explanation below are an attempt to close this loop of information in the easiest-to-understand format.

Firstly, manufacturers or producers procure virgin raw materials and/or recycle and make the desired end product. Once the product is ready, it is sent out for distribution through their existing channels of Stuckist's, wholesalers, and retailers.

Consumers then pick up the product, and returns are filed for faulty or damaged products. These returns or replacements are then repaired or refurbished according to the extent of the fault or damage.

Once the products are repaired, the consumers use them close to their end of life. When a product reaches this stage, it is discarded and picked up by a refurbishing/recycling company or manufacturer.

The acquired set of products is then scanned for completely faulty, or ones that cannot be recycled are set aside and disposed of. The remaining ones are recycled and transported back to manufacturers.

Examples

The process of closed-loop supply chain designs can be better understood with the help of a couple of practical examples. These shall give us an overview of the practicality and real-life application of the concept.

Example #1

PP Industries has a set of plastic recycling units. Their primary business activity is to collect end-of-life plastic products such as buckets, automobile components, air conditioning bodies, suitcases, and so on.

They collect these products directly from consumers or manufacturers with dead stock or discarded stock. They then grind them down, recycle these products, and send them back to manufacturers to process and mold the recycled plastic into desired products.

Example #2

The rise of electric vehicles (EVs) globally has not only led consumers to shift to a more sustainable way of commuting but has also given birth to a new industry altogether. Global leaders in the sustainable and renewable energy spaces have been running from pillar to post to ensure they have more than enough capacity to cater to the rising current volume and the future volume.

TES, one of the global leaders in this space, has a capacity of recycling batteries of about 15,000 tons per year. Given the rise in consumption and recycling volume, they are setting up units in the Netherlands, Korea, Australia, Hungary, and the USA to increase their recycling capacity to 40,000 tons. An increase of more than double their current recycling capacity.

Benefits

The benefits of closed-loop supply chain manufacturing have been apparent in the past few years. However, the points below give us a clear description of its specifics.

- These types of supply chains reduce the consumption of naturally occurring resources by recycling and reusing materials, leading to lower carbon emissions, energy usage, and waste generation.

- By refurbishing and remanufacturing used products or components, companies can reduce manufacturing costs associated with sourcing virgin materials. Moreover, they can also reduce disposal and waste management expenses.

- Adopting sustainable practices through this type of supply chain can improve a company's image and appeal to environmentally conscious consumers. The improved image leads to increased customer loyalty and market competitiveness.

- These systems help companies meet regulatory requirements related to waste management, recycling, and environmental protection. This, in turn, reduces the risk of fines or penalties for non-compliance.

- Closed-loop systems optimize the use of materials throughout their lifecycle, maximizing the value extracted from each resource and minimizing overall resource consumption. This efficiency translates into improved operational performance and resilience to supply chain disruptions.

Risks

While there are obvious advantages, there are also downsides to consider. The risks of a closed-loop supply chain design can be economical, environmental, or logistical. The specifics of the risks are as follows:

- These supply chains involve intricate processes for collecting, refurbishing, and reintegrating used products or materials, increasing operational complexity and requiring significant investment in infrastructure and technology.

- Remanufactured or refurbished products may not meet the same quality standards as new items, leading to potential customer dissatisfaction or product returns. Ensuring consistent quality across recycled or reused materials poses a challenge for closed-loop supply chains.

- These supply chains heavily rely on efficient reverse logistics networks to collect, transport, and process returned or used products. Any disruptions or inefficiencies in reverse logistics operations can impact the entire supply chain's performance.

- Compliance with regulations governing the collection, recycling, and disposal of used products or materials is essential for closed-loop supply chains. Non-compliance with environmental or waste management regulations can result in legal consequences, fines, or damage to the company's reputation.

- Implementing this design requires substantial upfront investments in infrastructure, technology, and workforce training. Companies must carefully assess the economic feasibility and long-term profitability of closed-loop initiatives to justify these investments and ensure a positive return on investment.

Closed Loop Supply Chain Vs Open-loop Supply Chain

The distinctions between a closed-loop supply chain management and an open-loop supply chain are discussed in the comparison below.

Closed Loop Supply Chain

- It involves the reuse, refurbishment, or recycling of products or materials within the supply chain.

- These supply chains emphasize sustainability by reducing waste generation and environmental impact.

- It enables companies to capture additional value from returned or used products.

- It promotes circular economy principles by keeping resources in use for as long as possible and minimizing the need for new resource extraction.

- The process requires efficient reverse logistics processes for collecting, sorting, and processing returned products or materials.

Open Loop Supply Chain

- It operates linearly, with products typically disposed of after their initial use.

- It focuses on producing and delivering new products to meet consumer demand without incorporating used or recycled materials.

- These processes generate significant waste and environmental pollution due to the disposal of used products.

- The process relies heavily on the extraction of raw materials to meet production needs, contributing to resource depletion and environmental degradation.

- It does not prioritize sustainability or resource conservation in supply chain operations.