Table Of Contents

What Is Bullwhip Effect?

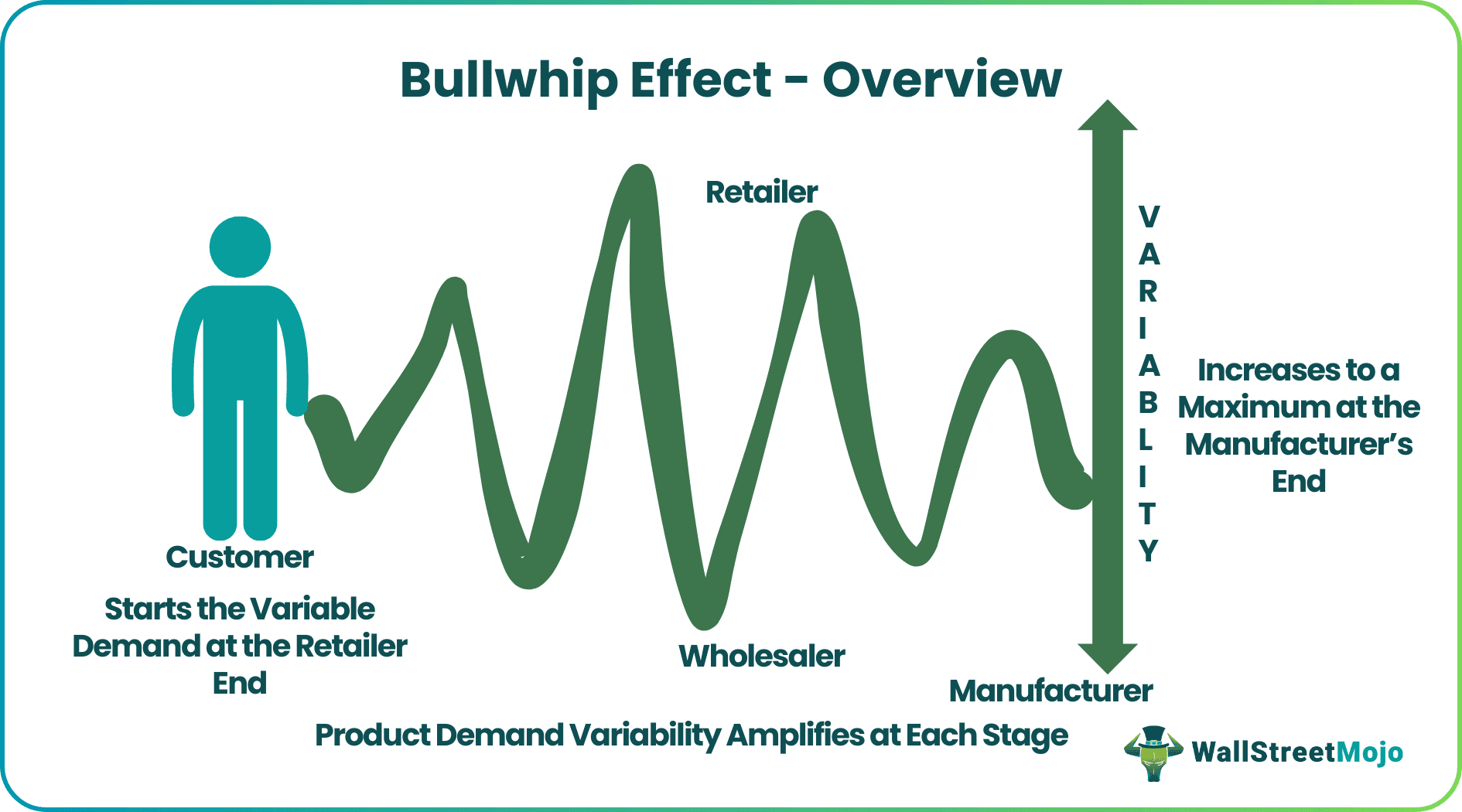

Bullwhip Effect (or whiplash) refers to occurring of a chain reaction due to the changes in demand at the customer end of the supply chain, making huge disruptive adjustments to the manufacturing end. It leads to either heavy or minimal buying of supplies. It results in out-of-stock or backorder or forces the companies to reduce product prices. Studying it helps managers and business owners avoid heavy losses.

The bullwhip effect supply chain is caused due to continuous variation of demand. Also, demand information distortion due to inconsistency in the supply chain leads to this effect. Customers hold that end of the supply chain's demand distortions affect the massive amplification of product demand leading to a chain reaction involving wholesalers, suppliers, and manufacturers.

Key Takeaways

- The bullwhip effect meaning implies an inverse ripple effect that tends to create an imbalance between supply and demand, leading to either shortage or excess inventory in the supply chain.

- Every step amplifies the effect due to the incorrect demand information flow at each supply chain management point.

- It hugely impacts the supply of products, customer satisfaction, revenue losses, and the company's brand image suffering from the effect.

- It starts at the customer end of the supply chain that goes on to affect the retailer, supplier, and manufacturer, wherein the effect at each stage gets highly amplified beyond control.

- Its prime cause is the lack of proper communication and improper lead time, which can be solved by improving communication.

- In addition, artificial intelligence and predictive intelligence can handle and minimize the occurrence and impact of the effect.

Bullwhip Effect in Supply Chain Explained

Bullwhip can be defined as a huge variability effect in the upstream from customer to manufacturing when small variations happen in demand for a product from the customer. It happens due to a lack of real-time communication and ill forecasting of demand by the manufacturer and the supplier. Bullwhip starts when a customer raises demand for a product with the retailer who notes it. The orders then get forwarded to the manufacturer. Any further orders by the retailer to the manufacturer will depend on the demand forecasting technique and customer demand observation.

After this, the manufacturers observe the demands placed on them for the orders. Based on the observation, it forecasts customer product demands to fulfill the retailers' demands. As the demand forecast by the manufacturer is based on retailers' orders rather than on customers' demands, its forecast often needs to be corrected. Further, the orders placed by the wholesalers vary more significantly than the customer demand noted by the retailer.

As a result, the manufacturer faces greater difficulty in accurate forecasting and inventory management of the customer product demand. Hence, the bullwhip effect gets implied from the above situation. Moreover, the increased variability in customer product demand leads to piling up more stock as safety stock or sustaining a higher production capacity than the demand of the retailer to match the retailer's product demand.

Hence, the impact of customer demand gets amplified at every step of the supply chain. Hence, the bullwhip effect comes into play leading to losses in revenue and products.

Bullwhip Effect Impact

Any irregular customer demand pattern may devastate the supply chain management and the brand image. Likewise, the whiplash effect greatly impacts the various facets of the product and the company's business. Let us look at some impacts of these effects:

- The manufacturer produces excessive stock.

- Shortage of stock occurs due to the effect of irregular demand.

- Disruption of the supply chain takes place.

- The storage cost of a warehouse increases.

- Shipment delays may happen.

- Transportation costs increases.

- Products may get spoilt.

- Customers opt for other brands.

- Refunds and cancellation of orders increases.

- Brand image may suffer.

- Revenue loss can also occur due to the above factors.

Causes & Solutions

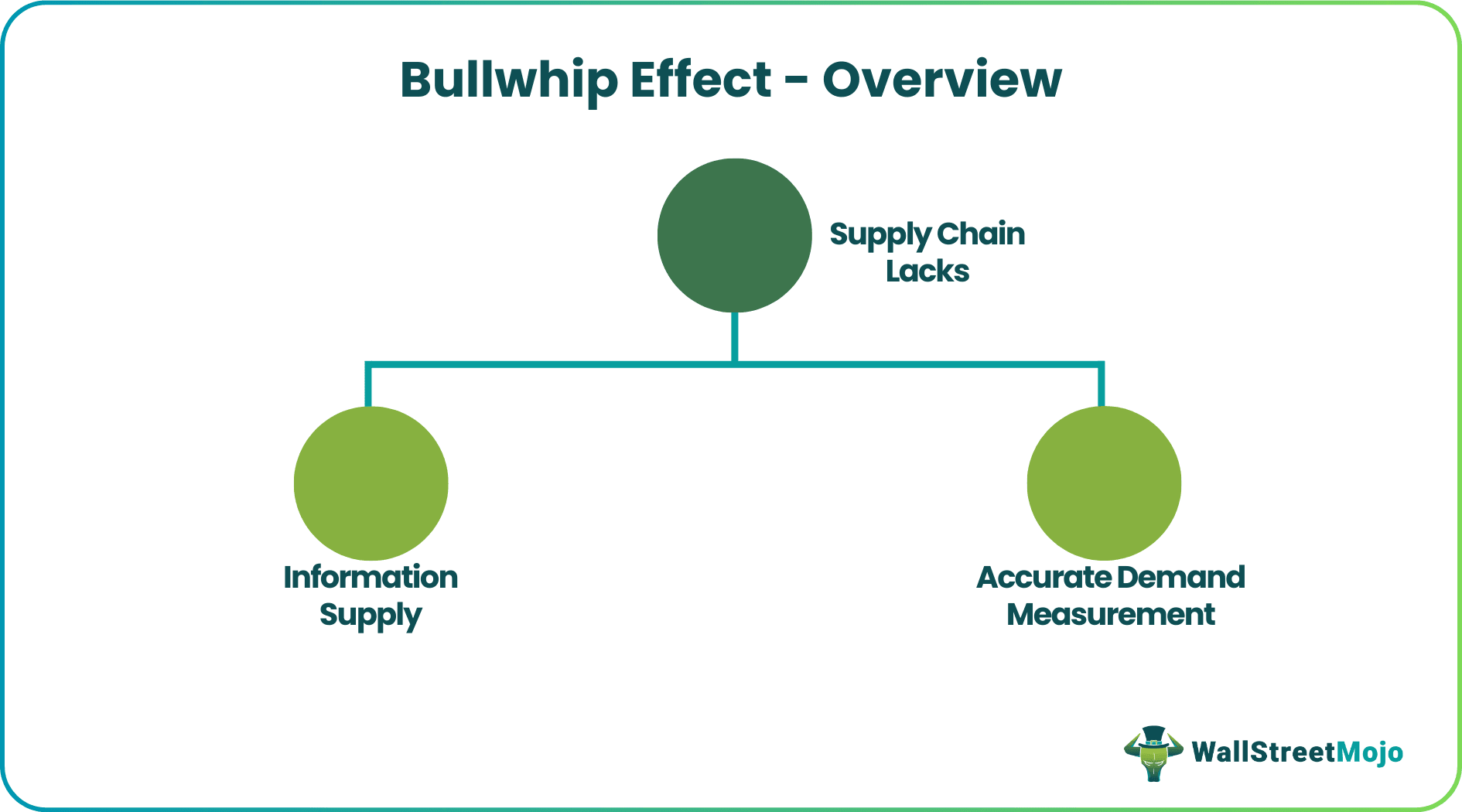

One finds four main causes of the bullwhip effect in a supply chain. Hence, one needs an appropriate solution for the issues. Here we discuss the bullwhip effect causes as listed below:

- First, manufacturing delays result in lead time difficulties.

- Supply chain stakeholders make the least optimal decisions at every point of the chain.

- Absence of proper alignment and communication among the supply chain stakeholders.

- Poorly judged reactions to demand expectations.

- Companies adopting the order batching of products waiting for orders built up before ordering supplies

- Unplanned discounts, cost variations, or other modes of price change disrupt the customer buying pattern.

- Making wrong demand forecasts of goods based on historical data rather than on real-time demand data of products

- Manufacturers use economies of scale in goods production.

- Putting up sales promotions online, on TV, in print, and advertisements.

Here are the solutions to the problems of the bullwhip effect in supply chains –

- Most importantly, communication between customer demand and the manufacturing point must be present.

- All the supply chain stakeholders, including manufacturers, suppliers, and retailers, must be aware of customer demand for products.

- Suppliers must be able to understand the needs of customers to maintain optimal inventory.

- Supply chain stakeholders must use various supply chain software like electronic data exchange and supplier & project portals.

- Producers may use artificial intelligence, predictive analytics, and the internet over things in demand forecast.

- Companies must explore and develop an approach based on demand within the supply chain management.

Examples

Let us look at some Bullwhip effect examples to understand the concept better:

Example #1

Recently, the executives of Hewlett-Packard (HP) examined the sales related to one bestselling printer at one of their key resellers. HP executives were surprised that, over time, some fluctuations in demand-supply (D&S) occurred. But, after careful examinations of the orders from the reseller, they observed huge swings in demand-supply of their printer.

Moreover, they got a bigger surprise upon analyzing the printer orders, creating much larger fluctuations of D&S in their integrated circuit manufacturing division. Thus, they termed it a bullwhip effect starting from customer to reseller to wholesaler to manufacturing division.

Example #2

Suppose the actual customer demand is 12 units. The retailers may forecast it as 15 units and keep 20 units with them as safety stock. Further, the wholesale would order 30 units from the manufacturer to get a discount on bulk purchases. Later, the manufacturer would order raw materials for 60 units to reduce costs. Thus, the bullwhip effect takes place.