Table Of Contents

Bottleneck Meaning

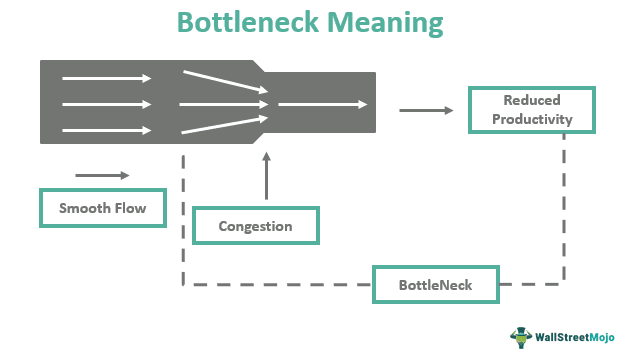

A bottleneck refers to a block or congestion that hampers the smooth operation of a system or a process. It can be seen in production, engineering processes, supply chain, etc. It severely reduces the efficiency and productivity of a process while simultaneously increasing costs and lead time.

Bottleneck management in organizations aims to reduce such occurrences. They employ measures to identify, eliminate, and avoid such circumstances as they can decrease the company's responsiveness to the market. Comprehensive actions to reduce such situations are often related to labor, logistics, manufacturing, and other organizational operations.

Key Takeaways

- Bottleneck refers to a situation that blocks a process and prevents it from functioning, thus reducing efficiency, productivity, and profits but increasing overheads.

- Further, it increases the lead time, which makes the organization less responsive to the market in terms of demand and supply.

- It can be caused by a lack of resources like raw materials, labor, and amenities like electricity, transportation, etc.

- Bottlenecks in production activities, supply chains, and even the economy should be eliminated, as they could threaten the survival of an establishment.

Bottleneck Explained

Bottlenecks, in layman's terms, mean the neck of a water bottle, usually the narrow part. When fluid flows out of the bottle, the volume decreases when it reaches the neck, i.e., the water particles are congested in the neck of the bottle.

Hence, the adoption of the term in the context of economics and commerce denotes an analogy. The routine operations of a firm are similar to the flow of water. Likewise, one can compare the neck of the bottle to any disturbances. These disturbances or obstacles can be less employee turnover, erratic supply of raw materials required for production, power cuts, and lack of resources like water.

Consider the example of a production bottleneck. A manufacturer produces 100 units of a commodity X every day. However, due to a union strike and fewer factory workers, production fell to 5 units daily. Here, the bottleneck is the union strike.

Such congestions or distractions have huge consequences and can often break a business. Hence, bottleneck management is extremely necessary. It involves identification, resolution or elimination, and finally, prevention.

Most bottlenecks are rather easy to identify, given their impact. However, some might affect the business gradually, and the business might take longer to notice them. Nevertheless, in any case, the management should waste no time resolving the congestion and getting the functions running smoothly again after identification.

Also, there should be no places for different blocks, i.e., prevention. Identification of earlier symptoms can help prevent such situations beforehand. However, managing disruptions depends on the source, external or internal.

The firm can control internal bottlenecks. Reasonable wages, proper maintenance of equipment, regular repairs, and effective administration and management can mitigate internal disturbances. But handling external disruptions can be a tough task. Here, the better option would be to have backup plans and alternatives to alleviate such disturbances' effects.

Managing Bottlenecks

Now, let's move on to the significance of managing bottlenecks. Such disruptions can potentially bring huge losses to a system, which is why controlling them is important.

The consequences of bottlenecks include an increase in lead time and overheads, reduced responsiveness to the market and subsequent widening supply-demand gap, uneconomical utilization of resources, loss of customers, and reduced market share and profits. Finally, it disrupts the efficiency and productivity of a firm.

Examples

Consider the examples given below to understand the concept of the Bottleneck.

Example #1

Let's begin with a simple example. Company X imports raw materials from country Y. Unfortunately, due to political tensions and riots in country Y, the company did not receive the next batch of materials needed for production. As a result, it was running out of stock, and there was no news from the supplier.

This is an extremely serious issue for an organization. But a resilient organization's management should always prepare for and expect such situations. For instance, they should have set aside some buffer or emergency stock, which they can use in such circumstances. Or they should have a backup supplier.

Example #2

CNBC recently reported that increasing vessel traffic from China to East Coast ports in the United States, like Savannah, Houston, and Virginia, might create new bottlenecks. Earlier, West Coast ports received this traffic, but due to talks of a labor strike on the West Coast, the traffic has shifted to the East, increasing by 18.9%.

The East Coast might be unprepared to deal with this high vessel turnover. The availability of rail and trucking companies, vessel congestion, and total turnaround time are the major causes of concern in these East Coast ports.

Bottleneck In Business

A business has to face many challenges – not just from competitors, customers, government, or even stakeholders. Many cases exist when employees and suppliers have given large corporations a tough time.

Production bottleneck is one of the most prominent ones seen in a business. Production can be halted due to employees, lack of materials, and basic resources like water and electricity. Even the condition of machines or equipment can affect the manufacturing process.

Other disturbances can include labor strikes, government interference, reduced demand, supply chain disruptions, supply-side issues, etc. Whatever the cause, it is a loss for the business. It increases the cost and time of production. But it can also lead to the loss of loyal customers and then profits.

Bottleneck In Supply Chain

Like business, the supply chain, too, has many factors acting on it. A supply chain is a network of many players, starting with the supplier, manufacturer, warehouses, distributors, delivery partners, and finally, customers. Hence, a disruption from any of these players can threaten the whole chain.

A supply chain doesn't merely ensure the flow of goods or services; capital and information flow also happen. Further, it is not safe to assume that disruptions from the supplier's or manufacturer's side are more dangerous. For instance, reverse logistics or product returns are also bottlenecks.