Table Of Contents

What Is Acceptance Sampling?

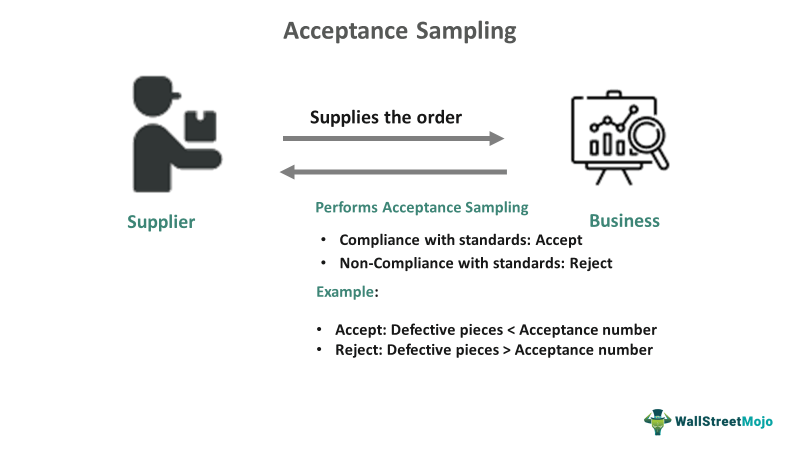

Acceptance sampling is a statistical technique used to inspect the quality of a batch of products. This quality control mechanism is applied to samples taken from the product batch. It involves comparing the number of defective pieces and the predefined acceptance number to accept or reject the batch.

The concept was popularised by Harold F. Dodge and Harry G. Romig from Bell Labs during World War II. The United States military then used the acceptance sampling method to test bullets. Furthermore, American statistician Walter A. Shewhart penned his work on acceptance sampling in the book "Statistical Methods from the Viewpoint of Quality Control" in 1939.

Key Takeaways

- The acceptance sampling method is to inspect or test the quality of a batch of products or services using statistical sampling.

- It is categorized into three types: Single sampling plan, double sampling plan, and multiple or sequential sampling plan.

- It saves time and money as fewer items are tested to conclude. In addition, the people who perform the sampling test can easily be trained. Hence it is an easy and affordable method of inspection.

- It does not assure the quality of the complete set of products from which the sample is derived.

Acceptance Sampling In Quality Control Explained

Acceptance sampling is a statistical method for evaluating if a batch of a product is fit for usage or not. In other words, it is the process of sampling applied to a whole batch of products received to determine the acceptability. The purpose is to ensure that the batch or lot meets a specific standard, which may vary depending on the company or industry.

In this methodology, random sampling is done from a group of products, and the sample products are tested. Decisions about whether to accept or reject the lot are made based on the sample test results. It is a compromise made between a complete inspection and no inspection.

Although this method aids in determining whether or not to accept a batch of a product, it is not an accurate estimation of the overall lot quality. Typically, the manufacturer gives the consumer a few samples from the lot. Then, the lot is approved by the consumer if there are fewer defects than the acceptable number.

Types Of Acceptance Sampling

There are three main types of the acceptance sampling plan, which are discussed below:

1. Single Sampling Plan

A single sampling strategy involves selecting a sample from the batch and testing it to see if it meets certain quality criteria. In other words, check whether the defective items are not above the acceptable limit. If the lot fails to meet the set criteria, the entire lot is rejected. This type of plan is employed for inspecting products produced in small batches.

2. Double Sampling Plan

A double sampling strategy involves selecting two samples from the lot and comparing them to see if they fulfill a predetermined quality standard. The method sets two acceptance numbers. The lot is accepted if the defective pieces are less than the smallest acceptance number (first acceptance number).

At the same time, the lot is rejected if the defective pieces are greater than the largest acceptance number (second acceptance number). A second sample is drawn if the number of defective pieces falls between the first and second acceptance numbers. Finally, the lot is accepted if the total number of defective pieces from two samples exceeds the second acceptance number.

3. Multiple or Sequential Sampling Plan

In multiple sampling, more than two samples will be used to arrive at a decision. For example, sequential sampling can have several samples. Following the sampling of the group, the test is carried out to determine whether or not it has passed a quality criterion. If it does not exceed the threshold limit, the procedure is repeated.

Example

Let us look at the acceptance sampling example to understand the concept better:

Manufacturer ABC Ltd sends a lot of 20,000 artificial flower bouquets to XYZ Ltd., an event management company. XYZ planned to conduct a quality check on the received bouquets. However, since inspecting and evaluating each bouquet will take time and money, they decided to use the acceptance sampling by attributes method. By using the method, XYZ Ltd strategizes a plan to inspect 30 bouquets.

Following the method, they randomly selected 60 flower bouquets from a lot of 20,000 flower bouquets. Then, they decided to accept the sample if the defective bouquets were below four. But, if there are more than three defects, XYZ Ltd. will reject the sample and sends the flower bouquets back to ABC Ltd.

Advantages

Some of the significant advantages of acceptance sampling are the following:

- First, it is an affordable method of inspection since the number of items that are tested is quite low in number.

- Less handling of the products indicates that the scope for the damage is low.

- The chances of inspection errors are low.

- An easy method to check quality and conformity with standards. If there are more defective items than the acceptable number, the entire lot will be rejected, pushing the manufacturer to improve the quality.

- The sampling method does not require much inspection time, workforce, and specialists to conduct the process.